Understanding Hydrogen’s Role in Decarbonization

Hydrogen offers a promising alternative to carbon-based fuels in our transition to a zero-carbon economy. While conventional vehicles and industrial processes rely on burning fossil fuels—releasing carbon dioxide and contributing to climate change—hydrogen production only water vapor as a byproduct.

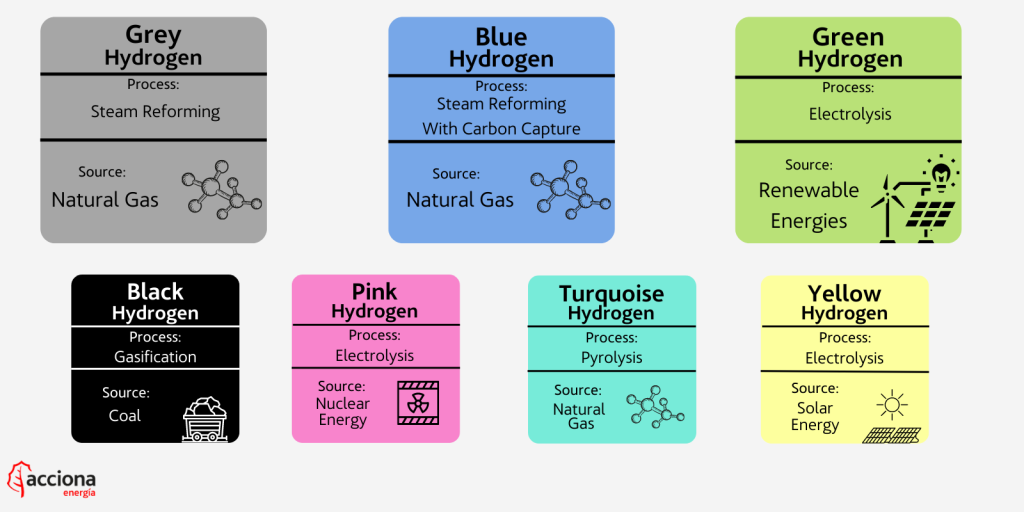

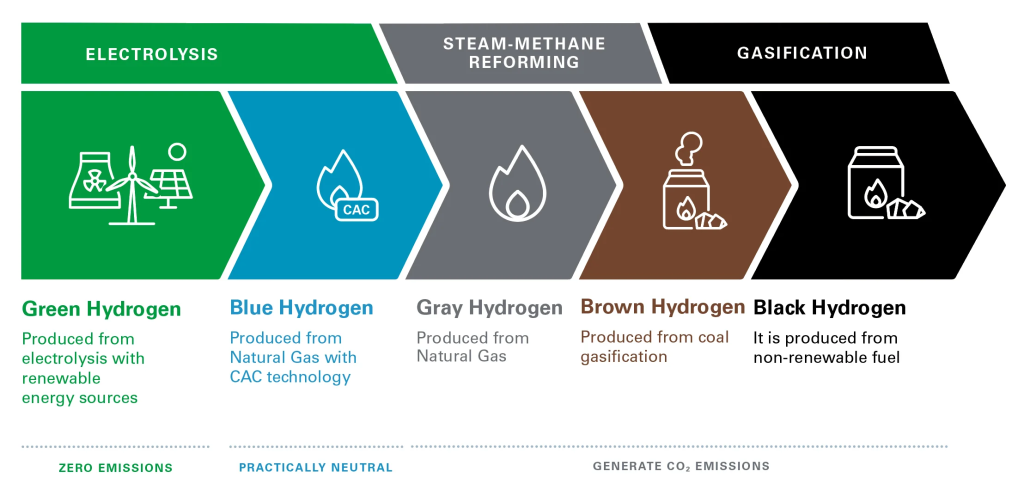

Despite being the universe’s most abundant element, obtaining usable hydrogen on Earth presents significant challenges. Various production methods have emerged, each designated by a specific color code to indicate its source and environmental impact.

Types of Hydrogen Production Methods

Black and Brown Hydrogen

Black and brown hydrogen come from coal gasification. This traditional method involves converting coal into hydrogen and carbon dioxide, resulting in significant carbon emissions. The process remains common in coal-rich regions but conflicts with decarbonization goals.

Gray Hydrogen

Currently the dominant form of hydrogen production, gray hydrogen uses steam methane reformation of natural gas. While more cost-effective than other methods, this process releases substantial carbon dioxide into the atmosphere, contributing to climate change.

Blue Hydrogen

Blue hydrogen represents an attempt to make natural gas-based production more environmentally friendly. The process mirrors gray production but incorporates carbon capture and storage (CCS) technology, claiming to capture up to 90% of emissions. The captured CO2 travels through pipelines for underground storage.

While oil and gas companies promote blue hydrogen as a cleaner alternative, researchers question its effectiveness and overall environmental impact.

Green Hydrogen

Green hydrogen represents truly clean hydrogen production, using electrolysis powered by renewable energy sources like solar and wind to split water into hydrogen and oxygen. This method produces no direct carbon emissions during the production process.

Pink Hydrogen

Similar to green hydrogen, pink hydrogen uses electrolysis but relies on nuclear power instead of renewable energy. This method offers another low-carbon option for hydrogen production.

Economic Considerations and Policy Impact

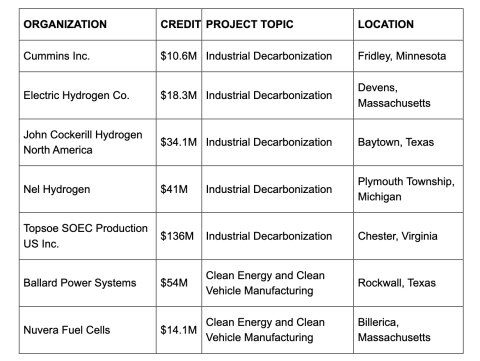

Historically, green and pink hydrogen have been the most expensive production methods. However, recent policy changes are reshaping the economic landscape. The Inflation Reduction Act introduced a $3 per kilogram tax credit for low-carbon hydrogen production. Analysis suggests this incentive could make green hydrogen production costs competitive with, or even lower than, traditional gray hydrogen.

The Future of Hydrogen Production

As decarbonization efforts intensify globally, the hydrogen production landscape continues to evolve. While gray hydrogen currently dominates the market, several key developments indicate a shift toward cleaner production methods:

Key Industry Trends and Opportunities

- Infrastructure Development: Major investments in hydrogen pipelines and storage facilities are creating the foundation for widespread hydrogen adoption. Companies planning hydrogen projects should consider proximity to these developing infrastructure networks.

- Technology Advancement: Electrolyzer efficiency continues to improve, with new technologies reducing electricity requirements for green hydrogen production. Organizations should monitor emerging technologies and consider pilot programs to test newer, more efficient systems.

- Market Growth: The hydrogen market is expected to expand significantly in industrial applications, transportation, and energy storage. Businesses should identify potential applications within their operations and develop implementation strategies.

- Policy Support: Governments worldwide are introducing incentives and regulations supporting clean production. Organizations should stay informed about regional policies and available incentives that could affect project economics.

- Cost Reduction Pathways: Declining renewable energy costs and economies of scale are expected to reduce green hydrogen production costs. Companies should develop long-term procurement strategies that account for these projected cost reductions.

Did You Think? Norway’s Carbon Capture Plant Advances Climate Technology