Deutsche ReGas and Höegh-LNG, two German LNG giants, have teamed up to develop the H2-Import-Terminal Lubmin, a floating hydrogen import terminal in Lubmin. This innovative project aims to transform the way Germany imports and utilizes green hydrogen, fostering a more sustainable energy landscape.

World’s First Floating Green Ammonia Cracker

The H2-Import-Terminal Lubmin is set to become the world’s first floating green ammonia cracker, producing 30,000 tonnes of hydrogen annually through the “industrial conversion” of green ammonia to green hydrogen.

Integration with Germany’s Hydrogen Core Network

The terminal will seamlessly feed hydrogen into Germany’s 9,700km hydrogen core network (HCN) through an existing feed-in point at Deutsche ReGas’ terminal in the port of Lubmin, ensuring efficient distribution throughout the country.

Adapting Marine Infrastructure for Cost-Competitive Hydrogen

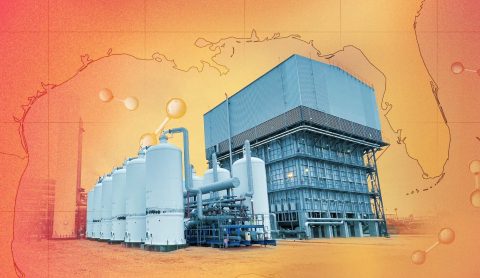

Höegh LNG’s ammonia cracking technology, integrated onboard a barge, serves as an industrial pilot for converting floating storage regasification units (FSRU). By adapting existing marine infrastructure, the project aims to provide cost-competitive hydrogen within the next few years.

Germany’s Quest for Energy Independence and Decarbonization

The H2-Import-Terminal Lubmin aligns with Germany’s goal of reducing reliance on natural gas while cutting emissions from its industry. Germany plans to import up to 70% of its hydrogen demand by 2030, securing future hydrogen suppliers and driving decarbonization efforts.

A Collaborative Effort Towards a Greener Future

Deutsche ReGas will provide the onshore terminal infrastructure and oversee the project’s coordination. Ingo Wagner, Managing Director of Deutsche ReGas, emphasized the terminal’s significance in decarbonizing the industrial regions of eastern and southern Germany.

The H2-Import-Terminal Lubmin is set to commence operations from early 2026, marking a significant milestone in Germany’s journey towards a cleaner, more sustainable energy future.