SunHydrogen’s developed an innovative technology that produces clean hydrogen from water using solar energy. This breakthrough has significant implications for transportation, industrial processes, and shipping sectors currently dependent on fossil fuels.

How SunHydrogen’s Water-Splitting Technology Works?

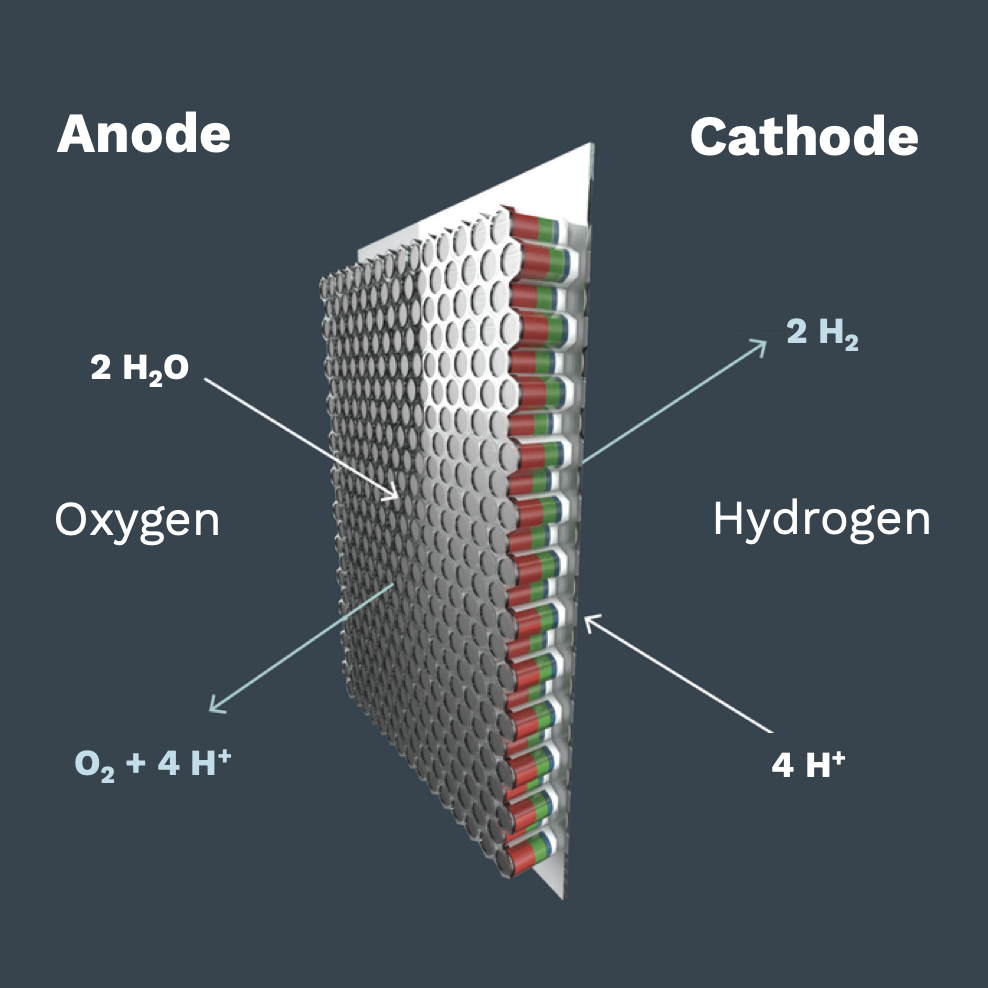

The core of SunHydrogen’s technology lies in Photoelectrosynthetically Active Heterostructures (PAH) – specialized nanoparticles that function as microscopic machines. Each PAH nanoparticle contains multiple layers that facilitate solar electrolysis, similar to natural photosynthesis in plants.

These nanoparticles harness solar energy to split water molecules, generating:

- Pure hydrogen for clean energy applications

- Oxygen as the only byproduct

Scalable Solar Hydrogen Production

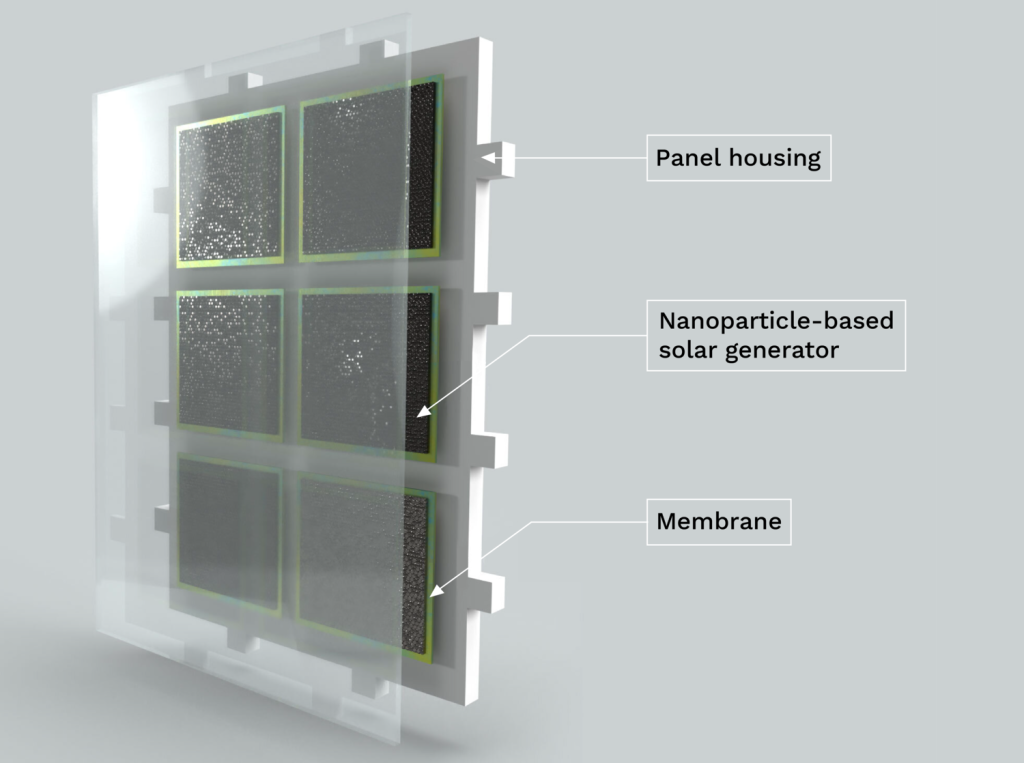

SunHydrogen’s technology integrates billions of nanoparticles into solar hydrogen panels. These panels offer versatile deployment options:

- Small-scale local installations

- Large-scale hydrogen production farms

- Flexible implementation across various geographical locations

Comparing Hydrogen Production Methods

Traditional Centralized Production

Traditional hydrogen production relies heavily on fossil fuels, presenting several significant challenges in the industry. The process generates high carbon emissions through oil, coal, and natural gas processing, while requiring substantial infrastructure investments for hydrogen transport. This conventional method results in a significant environmental impact, making it increasingly unsustainable in today’s climate-conscious market.

SunHydrogen’s Distributed Production

SunHydrogen’s approach addresses key industry pain points through an innovative distributed production system. This method enables zero-emission hydrogen generation while significantly reducing transportation infrastructure requirements. The localized production model proves more cost-effective than traditional centralized systems, making it a practical solution for widespread adoption.

Technical Advantages Over Conventional Electrolyzers

SunHydrogen’s technology provides distinct benefits compared to traditional electrolysis:

Cost Efficiency

- Eliminates need for expensive power electronics

- Operates independently of grid power

- Reduces overall operational costs

Operational Flexibility

- Functions with various water purity levels

- Maintains system reliability through panel redundancy

- Offers modular scaling options

Environmental Impact

- Produces zero direct emissions

- Requires minimal infrastructure

- Supports sustainable energy transition

This innovative approach to hydrogen production represents a significant advancement in clean energy technology, offering practical solutions for industrial and transportation sectors transitioning away from fossil fuels.

Did You Know? Green Hydrogen : The Future of Clean Energy Production